Food industry

Equipment for professional use in food , hospital, pharmaceutical and chemical industries where a high level of cleanliness and hygiene is necessary. Articles manufactured according to the requirements of Haccp protocols, FDA regulation, FEIBP standards.

Highest level of hygiene

Cleaning and hygiene of spaces (floors, walls, machinery and furniture) where products related to food or salubrity are handled, prepared, processed or packaged.

Easy to handle, ergonomic design

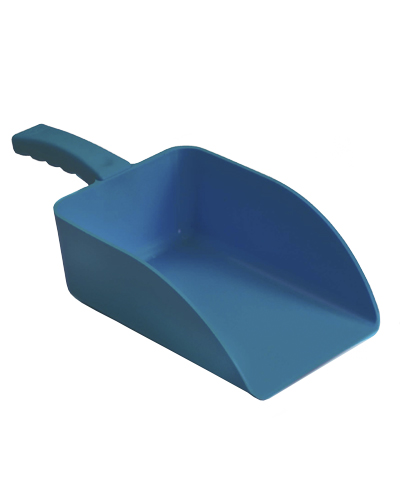

Very easy to use thanks to its very light polypropylene plastic manufacturing. In addition, we have multiple formats for manual surface cleaning such as floor cleaning.

Colour code system

Our products are available in 5 colors (blue, yellow, red, green and white) facilitating the implementation of a color code system differentiated by zones, avoiding cross contamination as recommended by the WHO (World Health Organization) and helping to comply with hygiene plans and HACCP protocols (Hazard Analysis and Critical Control Points).

Stand extreme temperatures

From -30º C to 80º C. It is recommendable to disinfect in autoclave up to 135ºC to avoid bacterial growth.

Durable, resistant and non-oxidizing materials responding to high hygiene and cleaning requirements.

Manufactured according to current legislation

Our entire range of brushes is manufactured in strict accordance with the rigorous standards defined by the F.E.I.B.P. (European Brushware Federation). Materials manufactured according to regulations (EC) No. 1935/2004, (CE) 2023/2006 AND (CE) 2015/174 modifying the EC 10/2011, and (EC) 1416/2016 regulations.

Manufactured with materials compatible with the FDA.

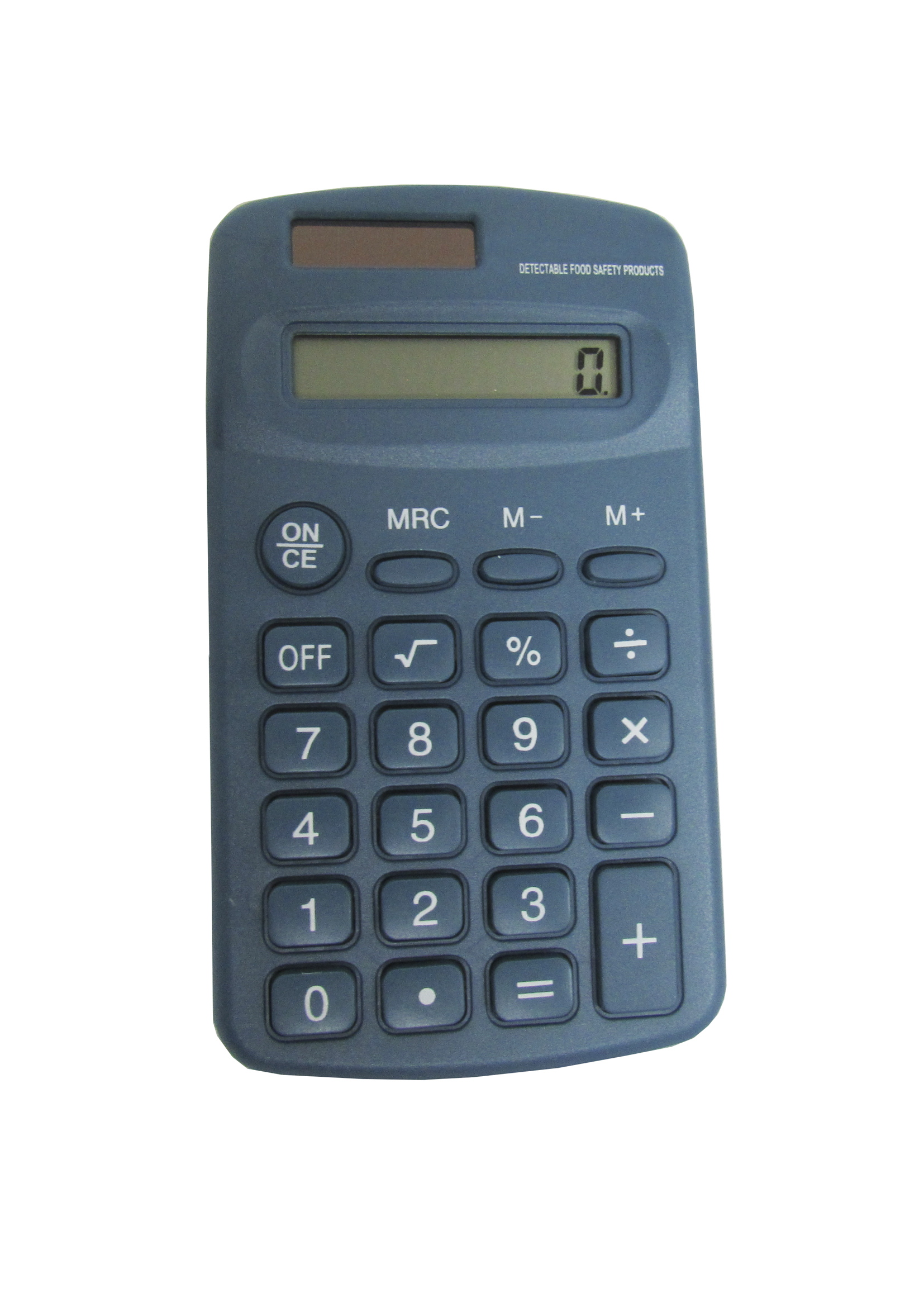

We also have a DETECTABLE RANGE

Our range of detectable products responds to the new requirements of food companies in risk management linked to the presence of foreign body in the product. All our products are fully detectable by means of control and prevention instruments applied to production lines such as magnets, metal detectors and X-rays.

Why use detectables?

Recommended in all those places where it is necessary to guarantee security by means of foreign body detection instruments to avoid reaching the final consumer avoiding the serious risk involved.

Many times the tools have been “lost in process” and later found by customers when they have eaten the contaminated food causing los of reputation and expensive recall of the food packs.

If a work tool or part of it is mixed with food in the production chain, the only way to detect it is through a metal and / or X-ray detector and dismissing this minimum part of the production (1-2 boxes of packaged product).

- Avoiding the risk of intake, possible complaints, bad reputation of the company and the destruction of large productions.

Especially recommended for the food, sanitary and pharmaceutical industry. It helps to comply with hygiene plans and HACCP protocols (Hazard Analysis and Critical Control Points).

- They withstand extreme temperatures. – Manufactured according to current legislation. – Durable and resistant materials.

Why use detectables?

Recommended in all those places where it is necessary to guarantee security by means of foreign body detection instruments to avoid reaching the final consumer avoiding the serious risk involved.

Many times the tools have been “lost in process” and later found by customers when they have eaten the contaminated food causing los of reputation and expensive recall of the food packs.

If a work tool or part of it is mixed with food in the production chain, the only way to detect it is through a metal and / or X-ray detector and dismissing this minimum part of the production (1-2 boxes of packaged product).

- Avoiding the risk of intake, possible complaints, bad reputation of the company and the destruction of large productions.

Especially recommended for the food, sanitary and pharmaceutical industry. It helps to comply with hygiene plans and HACCP protocols (Hazard Analysis and Critical Control Points).

- They withstand extreme temperatures. – Manufactured according to current legislation. – Durable and resistant materials.